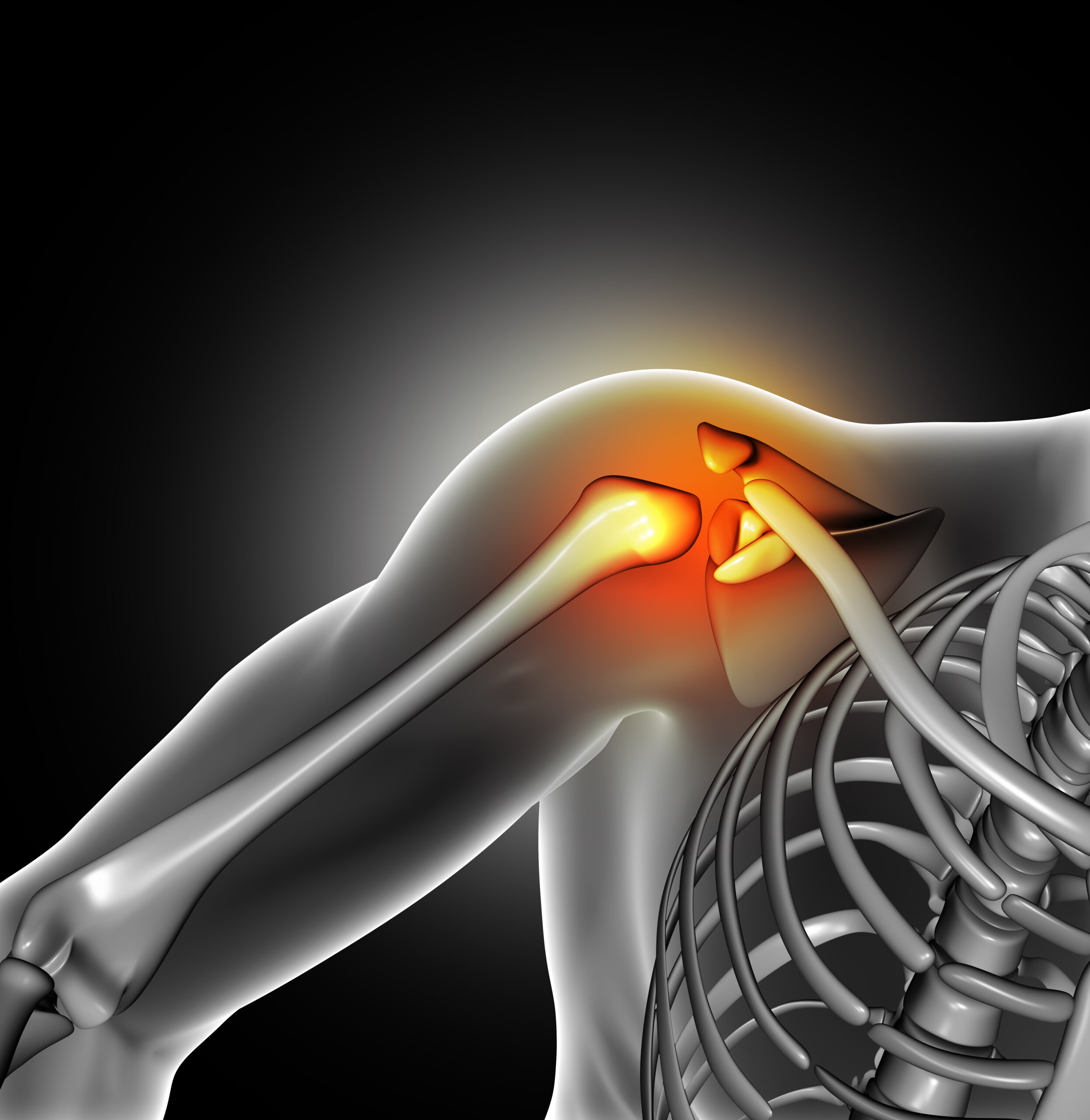

Definition of musculoskeletal disorders :

Musculoskeletal disorders (MSDs) represent a major challenge in a multitude of sectors. These disorders can encompass a range of problems, such as back, shoulder, arm, wrist and knee pain, with a significant impact on workers’ health and well-being. These disorders are caused not only by working conditions, but also by individual factors such as age and health status.

Risk factors :

There are several risk factors for MSDs :

- Individual factors : Such as age, gender, general state of health, history of injury or illness, level of fitness.

- Human factors : Like stress at work, high emotional demands, lack of control over work, difficult relationships with colleagues or management.

- Organizational factors : Such as high work rates, irregular working hours, insufficient breaks, lack of support from the employer.

- Environmental factors : Such as difficult working conditions (temperature, noise, lighting), unsuitable or defective equipment, or work areas that are too small.

- Activity-related factors : Such as carrying heavy loads, repetitive movements, uncomfortable positions, vibrations, awkward or prolonged postures…

The logistics sector :

We’re going to focus on musculoskeletal disorders in the logistics field, particularly for operators.

In fact, MSDs often affect logistics operators, as they are exposed to repetitive tasks, awkward postures and the handling of heavy loads, all of which cause a great deal of physical pain that can have a long-term impact on their health.

To reduce the risk of MSD among operators, logistics companies need to implement effective preventive measures. These may include the design of workstations with height-adjustable packing tables, for example, to reduce physical strain. As well as the use of appropriate handling equipment such as forklifts, electric pallet trucks and automatic dunnage dispensing systems, thus reducing manual handling and associated tiredness.

Two examples of ergonomic equipment :

The Logistibox :

Let’s take the Logistibox as a concrete example. It’s a dispenser for textile wadding (cushioning material), made of stainless steel and equipped with feet on castors for greater mobility, guaranteeing optimal layout of the operator’s workstation. Designed without an electrical system, it is practical and flexible to use.

This dispenser has a number of features. Its 45° tilting bowl, operated by a hydraulic cylinder, facilitates material extraction, reducing the physical effort required by the operator. What’s more, it features a dedicated storage area for wadding bags, eliminating the need to run back and forth to retrieve a fresh supply. This feature helps to alleviate operators’ musculoskeletal disorders by minimizing repetitive movements and heavy loads.

In short, the Logistibox represents an ergonomic and practical solution for handling textile wadding in the logistics sector, offering both operational efficiency and worker comfort.

To find out more about logistibox : https://www.blocbox.fr/distributeur-inox/

Handling exoskeletons :

Handling and assistance exoskeletons are revolutionising logistics operations by enabling workers to carry out arm tasks at height more efficiently and safely. These ergonomic devices offer physical support to users, reducing fatigue and the risk of injury associated with handling heavy loads or repetitive movements.

Using intelligent sensors and support mechanisms, exoskeletons distribute the weight of loads over the whole body, relieving pressure on the upper limbs. This assistance enables workers to maintain correct posture while reducing muscular tension, helping to prevent injuries and musculoskeletal disorders.

In warehouses and distribution centres, where picking and storage tasks often involve lifting and moving loads to varying heights, exoskeletons offer a significant advantage. By enabling operators to work more efficiently and reducing downtime due to fatigue, these devices help to improve productivity and safety in the workplace.

As well as their practical usefulness, exoskeletons also symbolise the constant evolution of technology in the service of ergonomics and the well-being of workers, paving the way for more efficient and more humane logistics.

To find out more about handling exoskeletons : https://gobio-robot.com/exosquelettes-industriels/ip-12-exosquelette-de-manutention/

Benefits :

By anticipating the management of these risks and using this type of equipment, logistics companies can not only improve the health and safety of their employees, but also increase their productivity and operational efficiency in the long term.

What’s more, by eliminating the need to go back and forth with stock nearby or even directly at the dispenser, this optimises the use of operators’ working time. This means better use of resources and increased order processing capacity on the logistics platform.

In short, the use of appropriate handling equipment offers many advantages for logistics platforms, including improved productivity, better management of operators’ working time and the prevention of MSD. These benefits translate into improved overall performance and greater competitiveness in the marketplace.

Prevention :

If you, as an employee, start to experience persistent joint or muscle pain, it is vital to discuss it openly with your employer and to consult a doctor without delay. If neglected, pain can develop into irreversible health problems. It’s crucial to understand that these pains are not exclusive to physically demanding professions; even those who work in an office environment, in front of a computer, can be affected because certain prolonged postures can have harmful effects on your body in the long term.